|

|

ADVANTAGES OF IPOL

- Comparing with conventional cutting tools, the advantages of PCD

Tools are as follows:

-

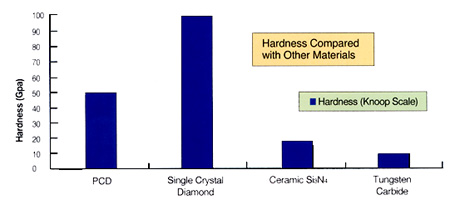

PHYSICAL PROPERTIES

| Property |

Unit |

PCD

Blanks |

Single

Crystal Diamond |

Ceramic

Si3N4 Hot Press |

Cemented

Tungsten Carbide |

| Ultimate

Compressive Strength |

Mpa |

6900-7600 |

8960 |

6800 |

4200-5600 |

| TRS

(Transverse Rupture Strength) |

Mpa |

480-1700 |

1050-4140 |

793 |

1700-2400 |

| Thermal

Conductivity |

W/mk |

543 |

600-2100 |

29 |

80 |

| Hardness

(Knoop Scale) |

Gpa |

50 |

40-100 |

18 |

13 |

| Thermal

Expansion Coefficient |

10^-6/�C |

1.5~3.8 |

0.8~4.8 |

3.5 |

4.3~5.6 |

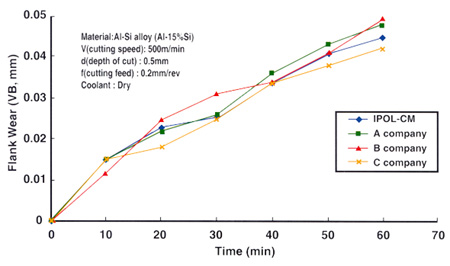

IPOL TURNING TEST

IPOL GRADES

| GRADE |

XUF |

CUF |

CF |

CM |

CC |

CXL |

| Nominal Grain Size |

0-1 micron |

0-2 micron |

4 micron |

10 micron |

25 micron |

25 micron |

| Microstructure |

|

|

|

|

|

|

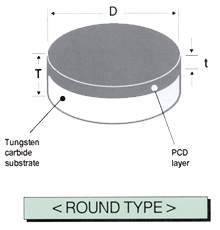

AVAILABLE PRODUCTS RANGE

ROUND TYPE |

| Product No. |

Size ( X D X T)

X D X T) |

| R360/75.0-T |

360deg. X 58.0mm X T |

| R360/60.0-T |

360deg. X 50.8mm X T |

| R360/25.4-T |

360deg. X 25.4mm X T |

R360/13.2-T

|

360deg. X 13.2mm X T

|

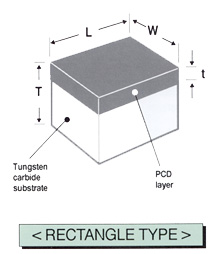

RECTANGLE TYPE |

| Product No. |

Size (L X W X T) |

| L36.0/ 36.0-T |

36.0mm X 36.0mm X T |

| L50.0/ 5.0-T |

50.0mm X 50.0mm X T |

| L25.0/ 3.0-T |

25.0mm X 25.0mm X T |

| L17.0/ 3.0-T |

17.0mm X 17.0mm X T |

| L10.0/ 5.0-T |

10.0mm X 10.0mm X T |

| L8.0/ 6.0-T |

8.0mm X 8.0mm X T |

| L13.0/ 3.0-T |

13.0mm X 13.0mm X T |

| L10.0/ 3.0-T |

10.0mm X 10.0mm X T |

| L11.5/ 2.0-T |

11.0mm X 11.0mm X T |

| L14.0/ 2.0-T |

14.0mm X 14.0mm X T |

| L6.0/ 4.0-T |

6.0mm X 6.0mm X T |

| L7.0/ 3.0-T |

7.0mm X 7.0mm X T |

| L5.0/ 3.0-T |

5.0mm X 5.0mm X T |

| L8.0/ 2.0-T |

8.0mm X 8.0mm X T |

| L5.0/ 3.0-T |

5.0mm X 5.0mm X T |

| L3.5/ 3.0-T |

3.5mm X 3.0mm X T |

| L5.0/ 2.0-T |

5.0mm X 5.0mm X T |

|

|

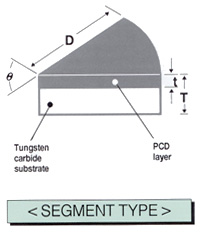

| SEGMENT

TYPE |

| Product No. |

Size ( X D X T)

X D X T) |

| S180/13.2-T |

180deg. X 13.2mm X T |

| S180/12.7-T |

180deg. X 12.7mm X T |

| S180/ 9.7-T |

180deg. X 9.7mm X T |

| S180/ 8.1-T |

180deg. X 8.1mm X T |

| S 90/ 6.5-T |

90deg. X 6.5mm X T |

| S 90/ 3.9-T |

90deg. X 3.9mm X T |

| S 60/ 12.7-T |

60deg. X 12.7mm X T |

| S 60/ 6.4-T |

60deg. X 6.4mm X T |

| S 60/ 3.8-T |

60deg. X 3.8mm X T |

| S 45/ 6.3-T |

45deg. X 6.3mm X T |

S 45/ 3.8-T

|

45deg. X 3.8mm X T

|

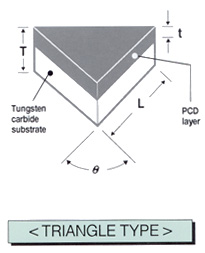

| TRIANGLE

TYPE |

| Product No. |

Size ( X L X T)

X L X T) |

| T 90/ 7.5-T |

90deg. X 7.5mm X T |

| T 90/ 6.5-T |

90deg. X 6.5mm X T |

| T 90/ 5.0-T |

90deg. X 5.0mm X T |

| T 90/ 3.8-T |

90deg. X 3.8mm X T |

| T 60/ 7.0-T |

60deg. X 7.0mm X T |

| T 60/ 5.0-T |

60deg. X 5.0mm X T |

| T 60/ 4.0-T |

60deg. X 4.0mm X T |

| T 45/ 6.2-T |

45deg. X 6.2mm X T |

| T 45/ 5.0-T |

45deg. X 5.0mm X T |

| T 45/ 4.0-T |

45deg. X 4.0mm X T |

|

|

- Non-listed specifications can be available on customers

request.

- Total thickness (T) is in the range of 1.0-3.2mm

depending on customers request.

- Diamond thickness (t) is in the range of 0.3-1.0mm

depending on customers request.

|

|